Soneera Water Activities – Power Generator Sector

Trials & Demonstrations

Soneera Water arrived in the USA in February 2014 and quickly manufactured a waste water treatment system in Phoenix. To date, Soneera Water has conducted demonstrations to most of the Cities in the Greater Phoenix Area, including the waste treatment facilities’ managers and engineers, APS and SRP. Soneera Water has performed a few significant trials where the system was challenged to meet difficult and at times almost impossible waste treatment scenarios. Below are two trials performed in the Power Generation Sector.

Tucson Electric Power Holding Ponds Trial

Tucson Electric Power (TEP) diverts its waste water to 7 million gallon storage ponds which are filled with algae, harsh chemicals and a silica loading exceeding 230 parts per million (ppm). The water is useless for any further industrial applications so it is forcibly evaporated. When the ponds are full, the waste water is chemically treated to render it neutral and is dumped to sewer where significant charges are incurred.

Tucson Electric Power (TEP) diverts its waste water to 7 million gallon storage ponds which are filled with algae, harsh chemicals and a silica loading exceeding 230 parts per million (ppm). The water is useless for any further industrial applications so it is forcibly evaporated. When the ponds are full, the waste water is chemically treated to render it neutral and is dumped to sewer where significant charges are incurred.

The Challenge:

Treat the concentrated waste water in the holding ponds to determine what, if anything, can be removed. The site manager actually said “good luck, because nobody can do anything with this water” and absolutely expected Soneera Water to fail.

The Result:

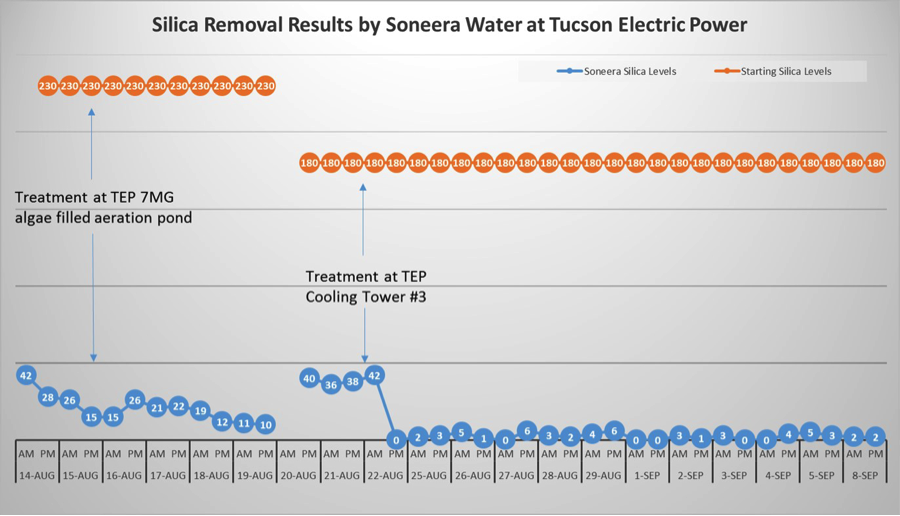

Soneera Water treated the waste water with the following results:

a. Removed more than 90% of the silica achieving results of 10 ppm.

b. Removed more than 95% of the algae, enabling the water to be reused.

Soneera Water demonstrated an alternate use for the waste water. It could be recycled back into the TEP cooling towers, used for dust suppression or a variety of non-potable industrial uses.

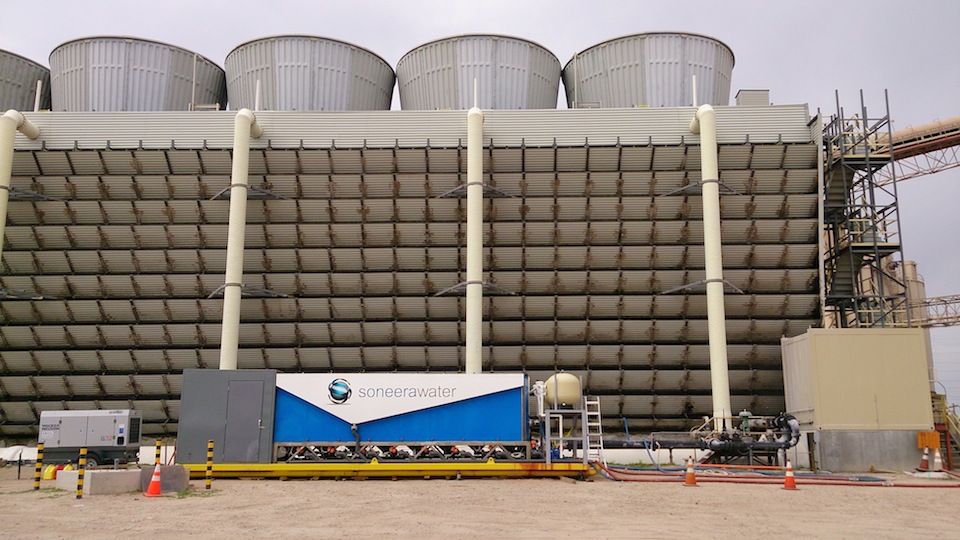

Tucson Electric Power Cooling Tower Trial

TEP dumps more than 275 gal/min of waste water from each of its cooling towers which then goes to the 7 million gallon storage ponds. This water is dumped because it contains concentrations of silica exceeding 180 ppm, which causes scaling, fouling and reduced efficiencies across the entire power generation cooling system.

TEP dumps more than 275 gal/min of waste water from each of its cooling towers which then goes to the 7 million gallon storage ponds. This water is dumped because it contains concentrations of silica exceeding 180 ppm, which causes scaling, fouling and reduced efficiencies across the entire power generation cooling system.

The Challenge:

Treat the dumped waste water by reducing the silica content by 50% and resupply it directly back into the cooling tower. Site management advised that 80% of all issues at TEP are generated by silica.

The Result:

Soneera Water treated the dumped waste water (blowdown) and removed more than 99% of the silica. This has the following benefits for TEP:

a. Significantly increased Cycles of Concentration

b. Zero chemical additives required to manage silica build up.

c. >90% of the blowdown waste water was returned clean. This reduces waste at the holding pond and reduces sewer costs.

d. Maintenance and labor is reduced by not having to descale the silica from the TEP cooling system.

e. Wear and tear on parts is significantly reduced by the removal of silica.

Combined Trial Results

Any queries can be directed to the following Soneera Water Executive

Darrell Behan

COO

Ph: +1 480 570 2703

E: darrell@soneerawater.com