Photo Gallery

Click to view larger image

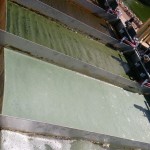

- Three water samples showing raw cooling tower water, the silica settled out and cleaned water ready to be returned to the tower.

- What is in your Cooling Tower water? (L-R): raw CT water; precipitating contaminants; cleaned water ready for reuse; and solid by-product of silica, calcium and other previously dissolved contaminants.

- Silica reduced from 230ppm to 11ppm

- US Air Force Site Visit

- Planning visit to Red Hawk Power Plant 640

- Demonstration of a treatment system to government and industry.

- Presenting the system to land developers and City Councilors at a demonstration in Phoenix AZ.

- Rather than fully discharge the cleaned water to the environment, a mine site chooses to create a wetlands with trees on the embankment.

- Cleaned water being discharged to the environment under an EPA License.

- Quality Assurance team conducting a 1000-hour spot-check of a system.

- A containerized treatment facility with the mine-specific health and safety modifications.

- A containerized treatment facility with the mine-specific health and safety modifications.

- Before & After treatment of combined raw sewage and kitchen waste.

- A treatment system at a municipal treatment facility in Arizona.

- The different colors achieved by the electrodes treating a range of contaminants in the waste water.

- A portable treatment system being delivered to a remote site in Arizona.

- Installing an electrode.

- Attaching power to the electrodes during site commissioning.

- Installing electrodes into a treatment system.

- A 40’ containerized system being delivered to site.

- A treatment system treating mine waste, storm water runoff with high concentrations of minerals and algal content.

- The 120ML holding pit being emptied, cleaned and discharged into the environment.

- A treatment system at a mine site removing waste water from a 120ML holding pit.

- Some of the cleaned water entering a National Park under an EPA License.

- Under an EPA License, the treatment facility discharges a mine’s clean water into a National Park.

- Skid mounted mobile system. 38’ x 8’. Capable of up to 175,000 GPD.

- Mining effluent. Before TSS – 188 mg/L, After TSS – 1 mg/L.

- The results from combined trade waste and sewage being treated in a single pass in 50 minutes.

- A treatment system operating at a municipal treatment plant.

- 740 ML of mine waste water to be treated.

- A treatment system at a mine site. The holding dams are 120ML and 740ML. The system is noticeable in the top left corner of the mine site.

- The result of treating all the raw sewage and kitchen waste from a remotely located restaurant.

- The water being cleaned at a mine site from a 120ML holding dam. The water is half way down after a few months’ treatment.